Taug qab Adjuster Cylinder Assembly

- Kev tsim cov compression coil caij nplooj ntoos hlav nrog txias rub caij nplooj ntoos hlav steel hlau

Rau lub tshuab dhos coil caij nplooj ntoos hlav, tom qab txheej txheem coil caij nplooj ntoos hlav, nws yuav tsum tau txiav tawm kom cais ob peb qhov txuas txuas rau hauv ib lub caij nplooj ntoos hlav.Rau qee qhov tseem ceeb, cov txheej txheem kev faib qhov siab dawb paug tuaj yeem ntxiv ua ntej sib tsoo lub ntsej muag kawg kom ntseeg tau tias kev sib tsoo zoo.Cov txheej txheem sib tsoo tseem tuaj yeem muab faib ua ntxhib sib tsoo thiab sib tsoo zoo, thiab deburring lossis chamfering tuaj yeem nqa tawm tom qab sib tsoo ntxhib.

- Manufacturing ntawm stretch coil caij nplooj ntoos hlav nrog txias drawn caij nplooj ntoos hlav steel hlau

Kev tsim khoom ntawm stretch coil caij nplooj ntoos hlav tuaj yeem ua tiav nyob rau hauv ib lub sij hawm nyob rau hauv lub caij nplooj ntoos hlav winding txheej txheem rau ib co raug shackles los ntawm kev siv lub tshwj xeeb tsis siv neeg caij nplooj ntoos hlav winding tshuab.Nws yog ib qho tsim nyog sau cia tias cov txheej txheem kev ntxhov siab tom qab coiling yog txhawm rau tshem tawm cov kev ntxhov siab uas tshwm sim thaum lub sij hawm coiling, thaum cov txheej txheem tempering tom qab ua lub nplhaib sib txuas yog txhawm rau tshem tawm cov kev ntxhov siab sab hauv thaum ua lub nplhaib sib txuas.Txawm hais tias ob txheej txheem no muaj kev ua haujlwm ntawm kev tshem tawm cov kev ntxhov siab sab hauv, lawv tsis tuaj yeem ua ke rau hauv ib qho txheej txheem, vim tias cov txheej txheem tempering yav dhau los muaj kev ua haujlwm ntawm "kev teeb tsa" los xyuas kom meej qhov tseeb qhov tseeb ntawm cov shackle.Thiab cov cua kub ntawm cov txheej txheem tempering tom qab yuav tsum tsis txhob siab tshaj qhov txheej txheem tempering yav dhau los.

- Tsim los ntawm torsion coil caij nplooj ntoos hlav nrog txias rub caij nplooj ntoos hlav steel hlau

Zoo ib yam li lub caij nplooj ntoos hlav ncab, kev tsim cov torsion coil caij nplooj ntoos hlav siv lub tshuab tshwj xeeb tsis siv neeg caij nplooj ntoos hlav winding.Rau qee qhov raug torsion caj npab, nws tuaj yeem ua tiav ib zaug hauv cov txheej txheem caij nplooj ntoos hlav winding.Muaj ob yam txheej txheem thev naus laus zis rau kev tsim cov torsion coil caij nplooj ntoos hlav.Ib qho yog txiav cov khoom mus rau ib qho ntev ua ntej, thiab tom qab ntawd yob lub caij nplooj ntoos hlav thiab lwm yam txheej txheem, xws li cov txheej txheem thev naus laus zis ntawm ob sab caj npab torsion caij nplooj ntoos hlav;Lwm qhov zoo ib yam li cov txheej txheem khiav ntawm lub caij nplooj ntoos hlav nro, tab sis txawv ntawm: lub caij nplooj ntoos hlav nro yog siv los ua lub nplhaib sib txuas, thaum lub caij nplooj ntoos hlav torsion yog siv los ua lub caj npab torsion.Vim hais tias cov kev taw qhia ntawm cov kev ntxhov siab nyob ib puag ncig rau kev ntxhov siab ua haujlwm, cov txheej txheem tempering feem ntau raug tshem tawm kom txo qis tus nqi siab tshaj ntawm kev ua hauj lwm kev ntxhov siab.Txawm li cas los xij, kev kho tempering tuaj yeem ua kom ruaj khov ntawm cov qauv ntawm cov khoom siv caij nplooj ntoos hlav thiab txo qhov deformation ntawm lub caij nplooj ntoos hlav torsion caj npab los ntawm kev sib tsoo thaum lub caij tsheb thauj mus los.Kev kho torsion muaj zog kuj yog ib txoj kev npaj rau ob peb qhov tshwj xeeb torsion springs.

- Coil caij nplooj ntoos hlav ua los ntawm caij nplooj ntoos hlav steel hlau nkag hauv lub xeev annealed

Alloy caij nplooj ntoos hlav steel hlau nkag rau hauv lub xeev annealed yog tsuas yog siv los tsim compression coil caij nplooj ntoos hlav.Nws cov txheej txheem thev naus laus zis txawv ntawm qhov tau hais los saum toj no.Nws yog tsuas yog quenched thiab tempered tom qab tsim, thiab normalized thaum tsim lub caij nplooj ntoos hlav kawg.Lwm cov txheej txheem yeej ib txwm zoo ib yam.

- Cov txheej txheem txheej txheem ntawm kub coil loj caij nplooj ntoos hlav

Lub caij nplooj ntoos hlav nrog cov khoom siv txoj kab uas hla loj dua 12 hli feem ntau hu ua lub caij nplooj ntoos hlav loj, uas feem ntau yog ua los ntawm cov txheej txheem kub.Lub caij nplooj ntoos hlav kub lub caij nplooj ntoos hlav yog qhov pib compression coil caij nplooj ntoos hlav.Kub coil springs yog tag nrho cov cored coil springs.Raws li rau lub coiling conical kauv compression caij nplooj ntoos hlav, nws yog ib qho nyuaj rau "qhib iav" (yob tawm lub suab) thaum coiling, yog li nws muaj lub luag hauj lwm ntawm qhib lub iav nyob rau hauv lub calibration txheej txheem.Tsis tas li ntawd, txhawm rau kom ntseeg tau tias qhov kub thiab txias, cov txheej txheem kho yuav tsum raug thiab nrawm.Txwv tsis pub, nws yuav tsum tau reheated thaum lub sij hawm quenching.Txhawm rau txhim kho lub neej qaug zog ntawm lub caij nplooj ntoo hlav kub, kev txhaj tshuaj peening yuav tsum tau nqa tawm kom deb li deb tau thaum muaj xwm txheej tso cai.

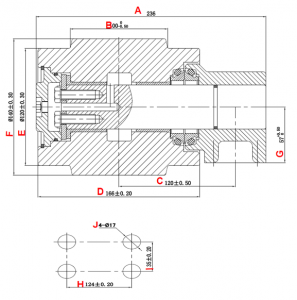

Cov qauv siv hluav taws xob muaj feem xyuam rau lub tog raj kheej tensioning tshiab siv nyob rau hauv cov cuab yeej tensioning ntawm lub excavator

Ib qho cuab yeej siv rau lub excavator thaum nruj nyob rau hauv hom tshiab Rose roj lub tog raj kheej, piston pas nrig sab hauv muab tso rau hauv lub tog raj kheej thaiv, lub tog raj kheej lub tog raj kheej ntawm lub lateral kawg teem roj qhov, cov roj txhaj qhov mus rau sab hauv ntawm lub piston pas nrig, cov roj. Lub qhov yog nyob rau ntawm qhov nkag mus rau lub teeb muaj me me roj khob, me me roj khob teeb muaj roj txiv mis, lub tog raj kheej ntsia hlau nyob rau hauv lub sab nrauv phab ntsa ntawm lub tog raj kheej lub cev, lub hau ntswj ntawm lub puab kawg txuas nrog ib tug piston pas nrig kawg tsau thiab lub ntswj ntsia hlau. pas nrig thiab piston pas nrig yog muab nrog lub nplhaib sealing, lub nplhaib sealing yog teem rau hauv qab kawg ntawm lub tog raj kheej lub cev; Lub qis kawg ntawm sab nrauv phab ntsa ntawm lub piston pas nrig thiab sab hauv phab ntsa ntawm lub tog raj kheej lub cev yog muab nrog cov lus qhia. Lub tes tsho, roj foob thiab tuav lub nplhaib; Sab nraud ntawm lub hau ntswj yog tsau nrog cov txiv ntseej, thiab sab nraud ntawm cov txiv ntseej yog muab nrog lub nres gasket.Cov qauv siv hluav taws xob muaj qhov zoo ntawm cov qauv tshiab, zoo li qub, ntau dua. Kev sib xyaw ua ke ntawm kev tshawb fawb, kev siv thev naus laus zis ntau dua, cov khoom siv txheem, lub zog siab, ruaj khov zoo dua, ruaj khov thiab ruaj khov, thiab ua haujlwm ntev dua.

| Cov ntaub ntawv nthuav dav |

|

| Nqe lus piav qhia: | Taug qab Adjuster Lub tog raj kheej Spring Recoil Assembly Rau Excavator Bulldozer Undercarriage ib feem |

| Qhov chaw ntawm keeb kwm: | Tuam Tshoj |

| Hom Lub Npe: | PT'ZM |

| Qauv nab npawb |

|

|

|

|

| Nqe: | Sib tham |

| Ntim cov ntsiab lus: | Fumigate seaworthy ntim |

| Lub sij hawm xa tuaj: | 7-30 hnub |

| Lub sij hawm them nyiaj: | L / CT / T |

| Lub sij hawm nqe: | FOB / CIF / CFR |

| Yam tsawg kawg nkaus kom muaj nuj nqis: | 1 pc ua |

| Muaj peev xwm muab khoom: | 10000 PCS / hli |

|

|

|

| Khoom siv: | 60Si2Mn / 45# / QT450-10 |

| Cov txheej txheem: | Forging |

| Ua tiav: | du |

| Hardness: | HRC45-55 |

|

|

|

| Zoo: | mining ua haujlwm hnyav hnyav high-end zoo |

| Lub sijhawm lav: | 24 hli |

| Kev pab cuam tom qab muag: | Video technical support, kev txhawb nqa online |

| Xim: | Dub lossis Cov neeg siv khoom xav tau |

| Daim ntawv thov: | Bulldozer & Crawler excavator |